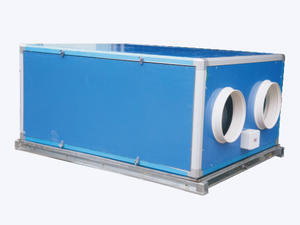

The cooling and heating integrated mold temperature machine includes two systems, two computer PC boards control their own systems, which are divided into heating system and cooling system, and automatically adjust the heating or cooling function according to the customer's use requirements. Able to achieve rapid heating and cooling. Today, Bobai introduces the operating precautions and principles of the cold and heat integrated mold temperature machine.

Precautions for the operation of the cold and hot integrated mold temperature machine:

1. Please try not to switch the operation switch continuously

The machine cannot be operated without water. Ensure that the suction port is in the water and air will not leak from the suction port.

3. Please set the temperature switch below 5°C to prevent the evaporator from freezing.

4. When the chilled water temperature reaches the set temperature, the compressor will automatically stop, which is normal.

5. In order to ensure the air-conditioning effect and maintain the best condition, please clean the condenser, evaporator and water filter regularly.

This feature of the cold and hot integrated mold temperature machine can improve production efficiency, suppress product defects, and reduce the occurrence of defective products. Mold cooling and heating integration technology can solve the two functions of heating and cooling at the same time. The temperature of the mold in a molding cycle is controlled by the heat medium and cooling water. Therefore, the advantages of the cold and hot mold temperature machine are more significant.

In actual industrial applications, a mold or other controlled object usually requires high and low temperatures. In terms of production technology, cold molds and hot molds often work together. Generally, hot molds require a circulating heating device to control the temperature. The cold mold that realizes the melting and hot pressing of material products requires a circulating cooling device to reduce its temperature and quickly cool the material products. Demoulding into the next production process, through cooling for chemical and physical action

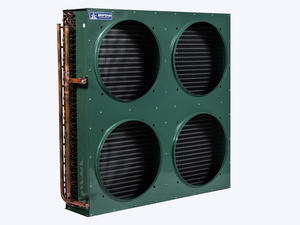

Zhejiang Beifeng Refrigeration Equipment Co., Ltd. has 35 years history of manufacturing refrigeration equipment. Currently, it has two processing bases located in Shengzhou, Zhejiang, with a production building of 60,000 square meters. It has set up three sales companies in Shanghai, Beijing, and Guangzhou, with strong technical force, advanced equipment, complete varieties and stable quality. As a leading China Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines manufacturers and Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines suppliers, We have a variety of condenser, evaporator production mold, heat transfer from 0.36 to 263.5 kw, We have a strong technical team,and we can develop and produce products according to the drawings or samples the customers offered. The company has a high-quality inspection center to detect the performance index of custom Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines and imported vacuum-type helium leak detectors for condensers and evaporators. It has a great influence in the national refrigeration industry and occupies a large market, with distributors in all major cities; It enjoys a high reputation not only in the domestic market, but also in the overseas market, and the products are exported to Europe, Southeast Asia, the Middle East, North America, Africa, etc.

Precautions for the operation of the cold and hot integrated mold temperature machine:

1. Please try not to switch the operation switch continuously

The machine cannot be operated without water. Ensure that the suction port is in the water and air will not leak from the suction port.

3. Please set the temperature switch below 5°C to prevent the evaporator from freezing.

4. When the chilled water temperature reaches the set temperature, the compressor will automatically stop, which is normal.

5. In order to ensure the air-conditioning effect and maintain the best condition, please clean the condenser, evaporator and water filter regularly.

This feature of the cold and hot integrated mold temperature machine can improve production efficiency, suppress product defects, and reduce the occurrence of defective products. Mold cooling and heating integration technology can solve the two functions of heating and cooling at the same time. The temperature of the mold in a molding cycle is controlled by the heat medium and cooling water. Therefore, the advantages of the cold and hot mold temperature machine are more significant.

In actual industrial applications, a mold or other controlled object usually requires high and low temperatures. In terms of production technology, cold molds and hot molds often work together. Generally, hot molds require a circulating heating device to control the temperature. The cold mold that realizes the melting and hot pressing of material products requires a circulating cooling device to reduce its temperature and quickly cool the material products. Demoulding into the next production process, through cooling for chemical and physical action

Zhejiang Beifeng Refrigeration Equipment Co., Ltd. has 35 years history of manufacturing refrigeration equipment. Currently, it has two processing bases located in Shengzhou, Zhejiang, with a production building of 60,000 square meters. It has set up three sales companies in Shanghai, Beijing, and Guangzhou, with strong technical force, advanced equipment, complete varieties and stable quality. As a leading China Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines manufacturers and Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines suppliers, We have a variety of condenser, evaporator production mold, heat transfer from 0.36 to 263.5 kw, We have a strong technical team,and we can develop and produce products according to the drawings or samples the customers offered. The company has a high-quality inspection center to detect the performance index of custom Intelligent integrated cooling and heating unit,Intelligent cooling and heating integral machines and imported vacuum-type helium leak detectors for condensers and evaporators. It has a great influence in the national refrigeration industry and occupies a large market, with distributors in all major cities; It enjoys a high reputation not only in the domestic market, but also in the overseas market, and the products are exported to Europe, Southeast Asia, the Middle East, North America, Africa, etc.

English

English عربى

عربى 简体中文

简体中文