The large heat transfer area of the air-cooled condenser is pivotal in enhancing its adaptability to ambient temperature in several ways:

Enhanced Heat Dissipation Efficiency: The significance of the large heat transfer area cannot be overstated when it comes to maximizing heat dissipation efficiency in the air-cooled condenser. This feature allows for a greater interface between the refrigerant and the ambient air, facilitating faster and more effective heat transfer. By maximizing surface area, the condenser can capitalize on convective heat transfer principles, ensuring that heat is expelled from the system efficiently. This efficiency is particularly crucial in scenarios where the ambient temperature is high, as it prevents the condenser from becoming a bottleneck in the cooling process. The efficient heat dissipation helps maintain lower operating temperatures within the condenser, reducing the risk of thermal stress on components and prolonging their lifespan.

Increased Cooling Capacity: The larger heat transfer area directly translates to an increased cooling capacity for the air-cooled condenser. This is essential for meeting the demands of applications that require consistent and reliable cooling performance, even under challenging environmental conditions. With a higher capacity for heat exchange, the condenser can effectively manage heat loads, ensuring that the refrigerant is cooled to the desired temperature regardless of variations in ambient conditions. This versatility is particularly valuable in environments where temperature fluctuations are common, such as outdoor installations or industrial settings where processes generate significant heat. By providing ample cooling capacity, the condenser enables systems to maintain optimal performance levels, enhancing efficiency and productivity.

Mitigation of Overheating Risks: One of the primary functions of the air-cooled condenser is to prevent the system from overheating, and the large heat transfer area plays a crucial role in achieving this objective. By efficiently dissipating heat, the condenser reduces the risk of temperature spikes that could lead to thermal runaway or component failure. This is especially important in applications where maintaining stable operating temperatures is critical for system integrity and reliability. The ability to mitigate overheating risks not only safeguards equipment but also minimizes the likelihood of downtime and costly repairs. By operating within a safe temperature range, the condenser ensures consistent performance over its operational lifespan, maximizing uptime and minimizing maintenance requirements.

Maintenance of Stability and Consistency: Stability and consistency are paramount in the operation of the air-cooled condensers, and the large heat transfer area contributes significantly to achieving these objectives. By effectively managing heat transfer, the condenser maintains a stable thermal environment within the system, ensuring that temperature fluctuations are minimized. This stability is essential for applications where precise temperature control is necessary to meet performance standards or regulatory requirements. Whether it's maintaining the temperature of a refrigerated storage facility or ensuring the proper functioning of a process cooling system, the condenser's ability to deliver consistent cooling performance is essential. By providing reliable operation over a wide range of ambient temperatures, the condenser enhances system efficiency and longevity, ultimately reducing total cost of ownership and enhancing overall operational reliability.

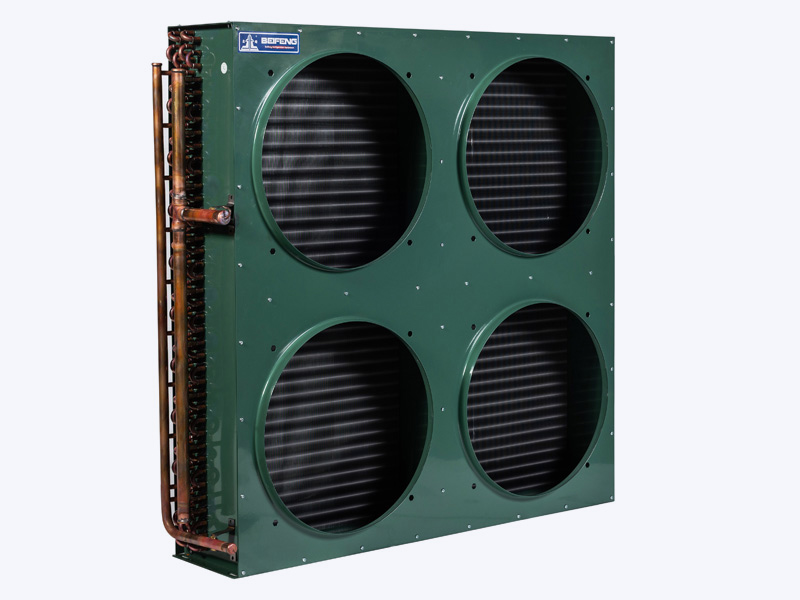

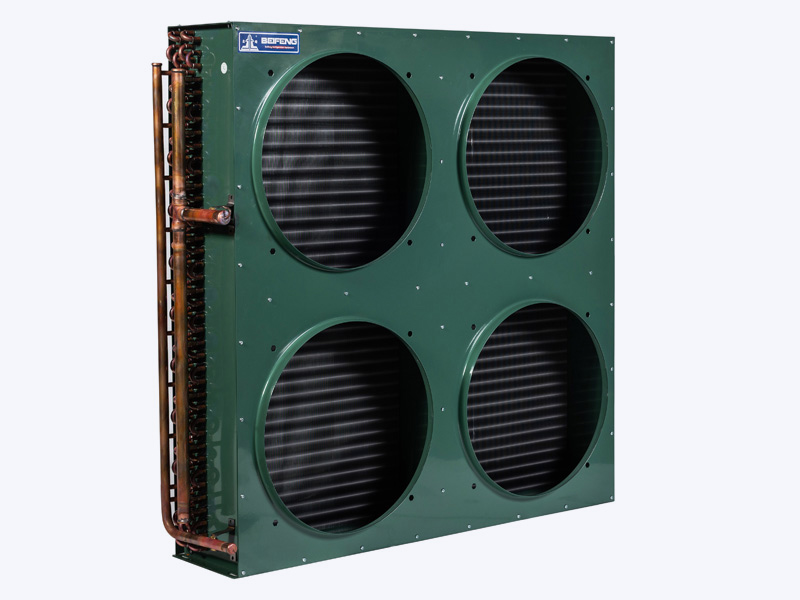

FN Serial Air-Cooled Condenser

FN Serial Air-Cooled Condenser

English

English عربى

عربى 简体中文

简体中文