Discover the heart of refrigeration with our comprehensive guide to semi-hermetic compressors. Gain a deeper understanding of the functionality and importance of these essential components in refrigeration systems.

Semi-hermetic compressors play a crucial role in the refrigeration process, as they are responsible for compressing and circulating the refrigerant within the system. Their unique design combines the advantages of both hermetic and open-type compressors, making them a popular choice in various refrigeration applications.

One of the key benefits of semi-hermetic compressors is their serviceability. Unlike hermetic compressors, which are sealed units that cannot be accessed or repaired, semi-hermetic compressors can be opened for maintenance and repairs. This allows for easier troubleshooting and replacement of components, ultimately reducing downtime and increasing the lifespan of the compressor.

The functionality of semi-hermetic compressors lies in their ability to compress refrigerant gas, raising its pressure and temperature. This compressed gas then flows to the condenser, where it releases heat and condenses into a liquid state. From there, the liquid refrigerant travels to the evaporator, where it absorbs heat from the surroundings and evaporates back into a gas. This cycle continues, providing continuous cooling or refrigeration.

Semi-hermetic compressors offer excellent efficiency and reliability, making them ideal for a wide range of applications. They are commonly used in commercial refrigeration, air conditioning systems, and industrial processes that require precise temperature control. Their versatility allows them to handle varying load demands and operate in different environmental conditions.

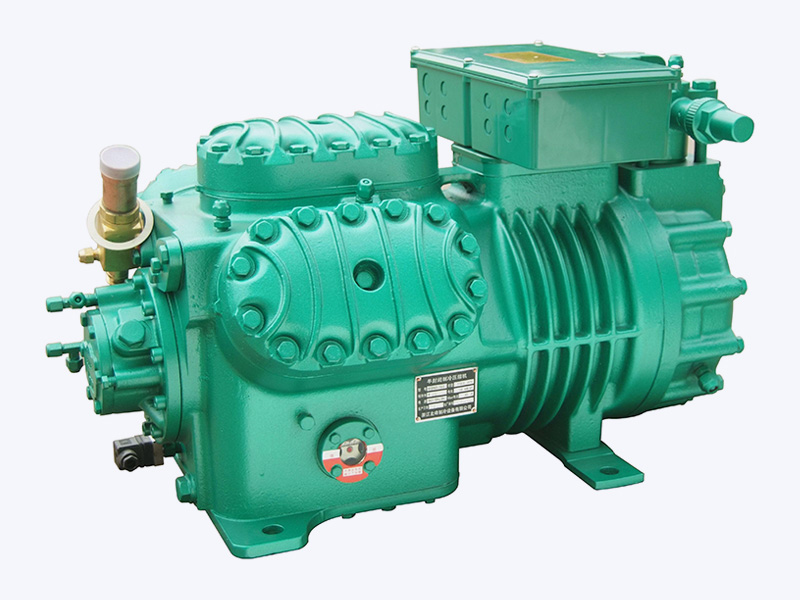

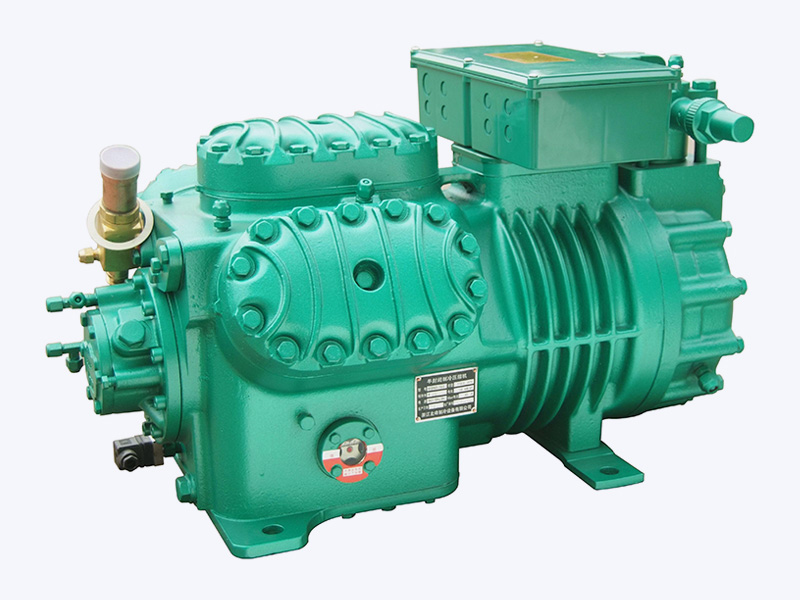

Semi-Hermetic Compressor(15HP-50HP)

Semi-Hermetic Compressor(15HP-50HP)

Excellent functions:

•High efficiency motors.

•Great gap control, high quality and low energy consumption in order to achieve a higher refrigerating capacity.

•Great mass balance of driving parts, less vibration and lower noise.

Special design for the construction:

•BFBV20 56H(Y) applies coil motor with low starting current.

•The materials which can reduce the friction are used.

•The valves are constructed with buffer activation.

Reliability protector:

•Electronic module protector is installed in the motor to control its operating temperature.

•BFBV20 84.5(Y) use oil pump for a good lubrication system.

•BFBV20 56H(Y) is equipped with auto protector of high pressure release valve.

•Crankcase heater is applied for preventing liquid strike.

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/webp/q/75)