An Air-Cooled Condenser is a device that converts gaseous substances into a liquid. In doing so, it releases latent heat that is then transferred to the surrounding environment. Ultimately, this helps to cool your home or office. This device is also useful for cooling industrial processes.

The Air-Cooled Condenser is a critical component of any refrigeration system. Its use helps reduce capital costs for a water reservoir and saves on water consumption during operation. The air-cooled condenser also solves the problem of diverting water from community use. In addition, it is environmentally friendly, lowering the carbon footprint of industrial plants. This makes it an ideal solution for water-constrained countries.

Air-Cooled Condenser systems designed by Holtec feature transformative air-cooling technology. These systems also reject waste heat and are compact, space-saving modular components. They are also effective for solving operational issues within cyclical power plants. To design an Air-Cooled Condenser that delivers optimum performance, Holtec engineers use computer models to calculate thermal-hydraulic performance and fatigue effects. They also study earthquakes and wind loads.

Air-Cooled Condensers also feature no fouling problems. However, they have some drawbacks, like high power consumption from the fan. They are not ideal for plants that require more than 5 TOR. Additionally, they are not efficient at high outside temperatures, as they require high air circulation. However, their compact size makes them an excellent option for small facilities. They do, however, require sufficient space to be installed.

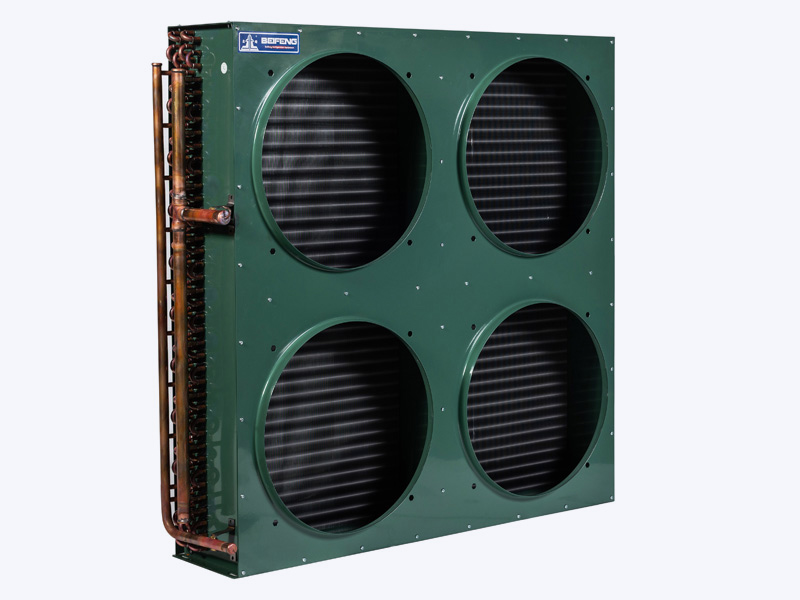

An Air-Cooled Condenser is an alternative to water cooling. A series of finned tubes draws ambient air across the tubes to extract latent heat from low-pressure steam. Mechanical fans are used to force the air over the heat exchangers. This option is becoming the standard for most dry-cooled power plants. These air-cooled condensers are available in a variety of designs and materials.

Air-Cooled Condensers have been installed in a number of power plants throughout North America. Another alternative is direct dry cooling. This method condenses turbine exhaust steam inside finned tubes and cools them with ambient air. However, ambient air is not as effective as water. Aside from natural draft, the air can also be circulated through the system by fans.

An Air-Cooled Condenser is generally simpler to install and requires less space. Air-Cooled Condensers do not have fouling and disposal issues. However, they are more expensive than their water-cooled counterparts. A typical air-cooled condenser may cost two or three times more than a water-cooled condenser.

Air-Cooled Condensers are often used in thermal power plants. Because they do not require large amounts of water, they are able to be constructed in regions where water is unavailable or expensive. They consist of a series of modules that contain fin tube bundles. The cooling air is forced across the heat exchange area of the fin tubes.

English

English عربى

عربى 简体中文

简体中文