When the unit is cooling, the compressor sucks the low-temperature and low-pressure refrigerant in the evaporator into the cylinder, and after the compressor works, the refrigerant vapor is compressed into high-temperature and high-pressure gas

And enter the condenser through the exhaust pipe. The high temperature and high pressure refrigerant gas exchanges heat with the cooling water in the condenser, and transfers the heat to the cooling water belt, while the refrigerant gas condenses into high pressure liquid. The high-pressure liquid discharged from the condenser is decompressed through the throttling of the thermal expansion valve and then enters the evaporator. In the evaporator, the low-pressure liquid refrigerant absorbs the heat of the chilled water and vaporizes it, cooling the chilled water, and becomes the necessary low-temperature water. The vaporized refrigerant gas is sucked and compressed by the compressor again, and then discharged into the condenser, so that it circulates every week to realize the cooling of the chilled water.

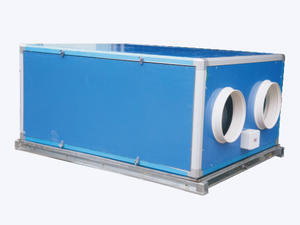

The chilled water discharged from the unit enters the indoor fan coil unit, variable air volume air conditioner and other terminal devices. During the heat exchange process between the indoor and the convective air, the water absorbs the heat of the indoor air (releases heat to the indoor air), causing the temperature to rise After the indoor air passes through the indoor heat exchanger, the temperature rises and the chilled water enters the unit again under the action of the pump to achieve the purpose of continuous refrigeration.

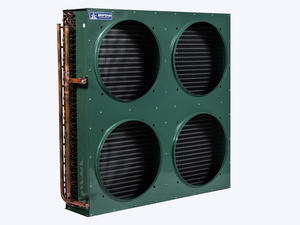

Shell And Tube Double Stage Water-Cooled Condenser

Since the first heat exchanger was made in 1984,based onthe precision digital controlled machine and high efficient heatexchanging tube used,reliable and high quality products aremanufactured by Beifeng.There are two series products condenserand evaporator about 11 various products, including fresh watersingle or double condenser,liquid condenser received,and straightor“ U”tube single, double and triple evaporators etc. Products willbe made of excellent material with precision processing techniqueand strict quality assurance acceptance standards.The productswill be delivered accompanying with the specifications in details andquality audit fromQA department.

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)